EKU to Reflect Its Automotive Success to the Railways

Doğukan Dudaroğlu indicates that the company aims to achieve success in the railways sector similar to they did in the commercial vehicle sector, and they have invested in a new foundry in this direction.

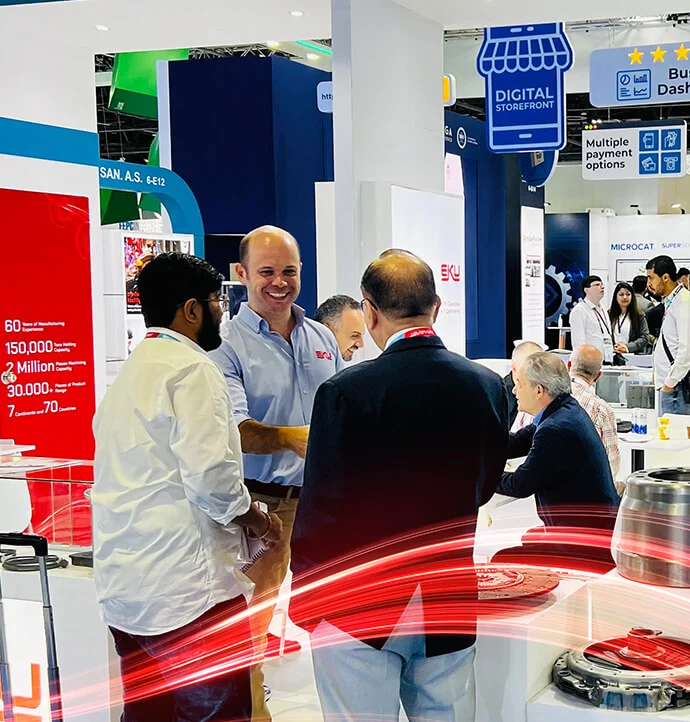

Manufacturing brake drums and brake discs for the domestic and international OEM, OES and renewal markets with an annual casting capacity of 150,000 tons on an area of 50,000 square meters, including 35,000 square meters of closed area in TAYSAD Organized Industrial Zone, EKU is among the largest 500 exporters in Türkiye and the largest 50 exporters of the automotive sector. EKU General Manager Doğukan Dudaroğlu indicates that the company aims to achieve success in the railways sector similar to they did in the commercial vehicle sector, and they have invested in a new foundry in this direction.

RailwayTurkey: Could you introduce yourself briefly?

Doğukan Dudaroğlu: After graduating from Koc High School in 2003, I completed my bachelor degree in Reading University Department of Economics in England in 2007. After my military service, I pursued my career in the field of investment banking in 2009 on the side of corporate mergers and private equity funds. As the representative of the 3rd generation, I have performed my task as the General Manager of EKU for 6 years.

RailwayTurkey: Could you give information about the corporate identity of Eku?

Doğukan Dudaroğlu: EKU meets the needs of the automotive heavy commercial sector all over the world with its wide range of brake groups. Taking advantage of technological developments, the company has been producing environmentally friendly brake drums and brake discs to meet high quality standards for over 60 years .EKU is an automotive company manufacturing brake drums and brake discs for the domestic and international OEM, OES and renewal markets with an annual casting capacity of 150,000 tons on an area of 50,000 square meters, including 35,000 square meters of closed area in Çayırova-TAYSAD Organized Industrial Zone. Our company has 500 employees. EKU is among the largest 500 exporters in Türkiye and the largest 50 exporters of the automotive sector.

World's First Foundry to Receive an Environmental Award: EKU

RailwayTurkey: Could you evaluate the global position of Eku in its sector on the basis of the products? Could you give information about your production capacity?

Doğukan Dudaroğlu: We are the first foundry in the world to receive an environmental award. EKU, the first domestic manufacturer to export brake drums and brake discs from Türkiye to Europe and America, has become a world giant in the production of safe brake drums and brake discs. We have an annual production capacity of 1,500,000 units and export to more than 100 countries on 7 continents.

RailwayTurkey: How much of your production do you export? Could you give information about your export markets?

Doğukan Dudaroğlu: EKU exports 90% of its production. Our largest markets are North America, Eastern Europe and Western Europe.

We Take Active Role in Railway Sector with New Foundry Investment

RailwayTurkey: You manufacture for the railway sector as well. Do you have new investment plans for your railway production? What are your goals in the railway sector?

Doğukan Dudaroğlu: In recent years, we have exported Train Discs to France, Germany and India. Since the demands in the automotive commercial vehicle group filled our production capacity, we had to direct our production to the commercial vehicle group. Our strategic goal is to grow in the railway sector. With our new foundry investment, we will take an active role in this sector. We aim to achieve success in the railways sector similar to we did in the commercial vehicle sector by using the advantages of our experience in vermicular casting.

Our Capacity to Increase by 200% in 2025

RailwayTurkey: Do you have new factory investment plans at home or abroad? What are your short and medium scale goals?

Doğukan Dudaroğlu: With our new investment, whose installation will begin in 2024, we will increase our capacity by 200% in 2025. In the medium and long term, we aim to be a brake system manufacturer.

RailwayTurkey: Could you inform us about your investments in digitalization?

Doğukan Dudaroğlu: EKU has created a 5-year digital transformation roadmap by conducting a digital maturity analysis. We aim to monitor the production area digitally with the production monitoring system and digital twin applications.

We aim to be a "Smart Factory" by integrating the industrial internet of things (IIoT), manufacturing execution system (MES) and enterprise resource planning (ERP) on the same digital platform.